DMC PROCESSES FOR OIL AND GAS CONDENSATE TREATMENT FOR HYDROGEN SULFIDE AND MERCAPTANS

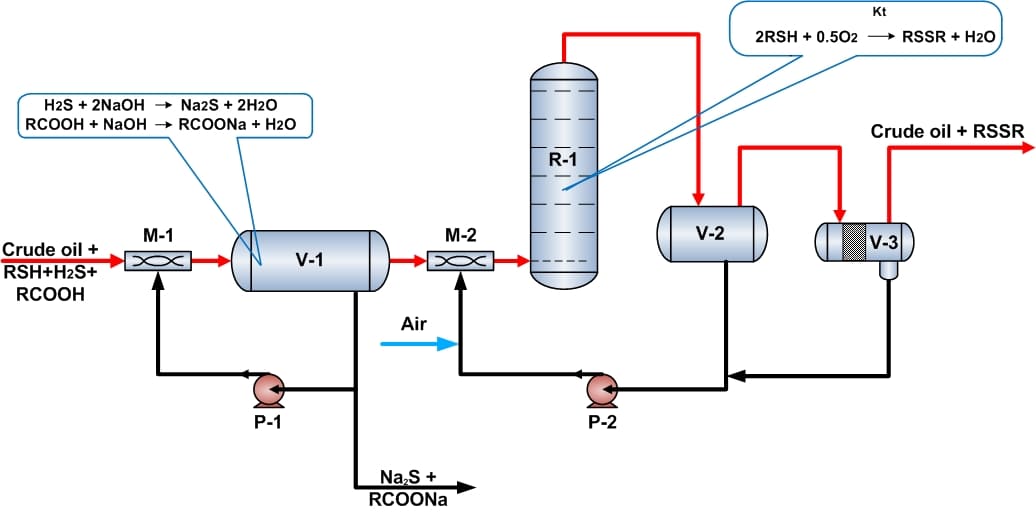

The process is used for treating light oils and gas condensates for hydrogen sulfide (from 50 to 5 ppm) and low molecular weight С1-С2 mercaptans (from 600 tо 20 ppm).

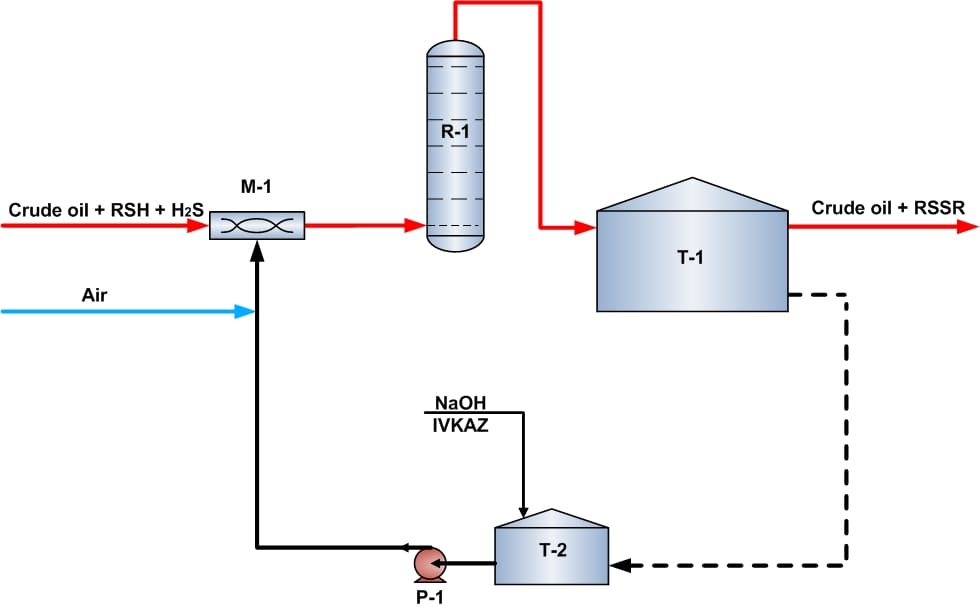

The process is used for treating heavy oils and gas condensates for low molecular weight С1-С2 mercaptans (from 300 to 20 ppm) and hydrogen sulfide (from 50 tо 5 ppm) on oil fields.

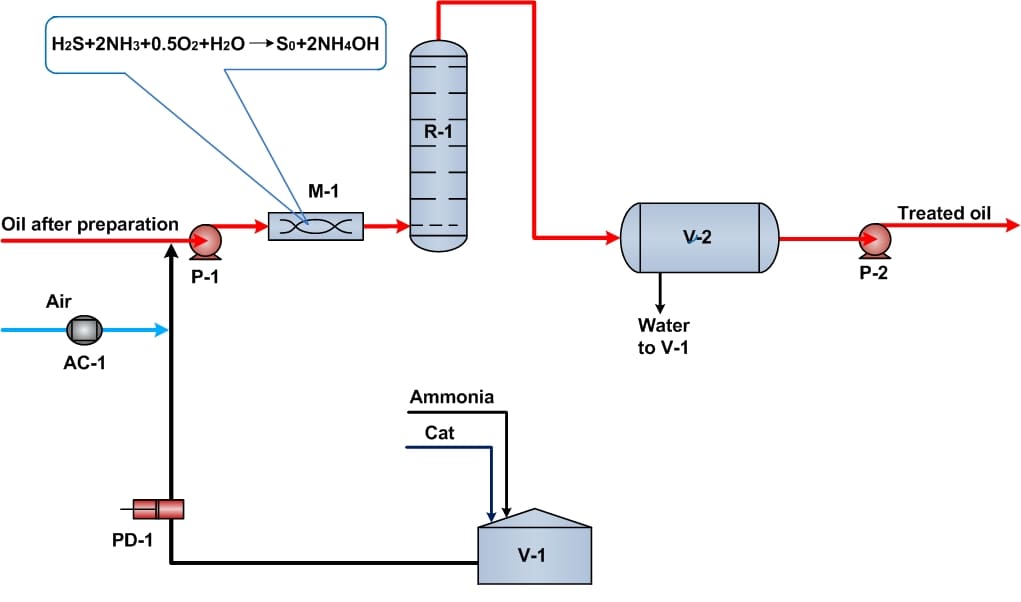

The most efficient and energy-conserving process for treating oil with high hydrogen sulfide content (from 500-700 ppm tо 5 ppm) is liquid-phase oxidation of hydrogen sulfide and mercaptans using aqueous-ammonia solutions of IVKAZ catalyst.

The process is used for treating light oil and gas condensates for hydrogen sulfide and low molecular weight С1–С3 mercaptans without contact of oil with air. DМС-2 plants were put into operation by modification of DМС-1 plants on JV “Tengizchevroil” (Kazakhstan).

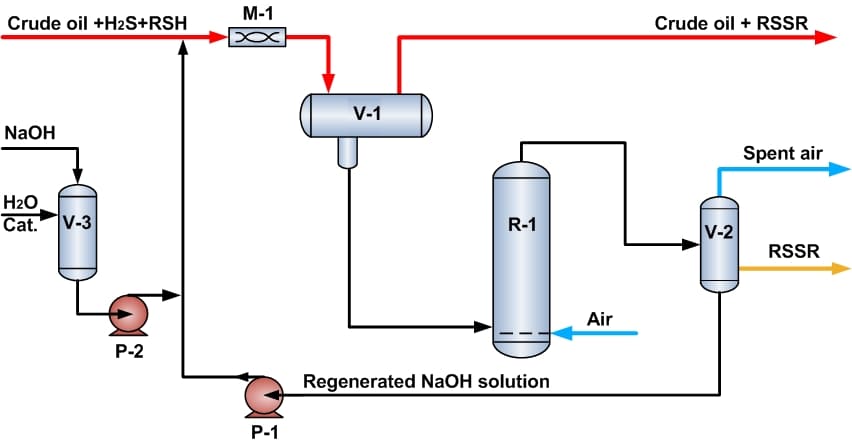

The process is used for treating oils and gas condensates for hydrogen sulfide (from 100 tо 5 ppm) and low molecular weight С1-С4 mercaptans (from 4000 tо 50 ppm).

Why are formaldehyde-based adsorbents (scavengers) of hydrogen sulfide and mercaptans not to be used?

Why are formaldehyde-based adsorbents (scavengers) of hydrogen sulfide and mercaptans not to be used?