DMC-1M process

The process is used for treating heavy oils and gas condensates for low molecular weight С1-С2 mercaptans (from 300 to 20 ppm) and hydrogen sulfide (from 150 tо 5 ppm) on oil fields.

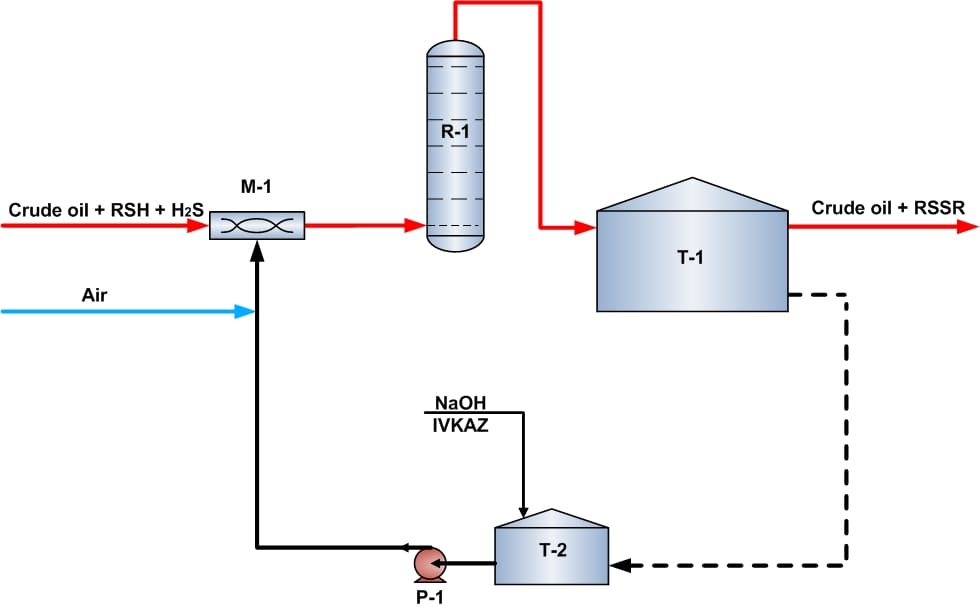

The oil, stoichiometric quantity of air for oxidation of hydrogen sulfide and С1 ─ С2 mercaptans and aqueous-alkaline solution of IVKAZ catalyst (CC) in an amount of no more than 5 liters per ton of the oil are mixed in a tube mixer М-1 and orifice mixer-reactor R-1. Intensive mixing of the reagents and selective oxidation of С1 ─ С2 mercaptans to disulfides and oxidation of hydrogen sulfide to elemental sulfur and sodium thiosulfate takes place in reactor R-1 at a temperature of 30─60oС and a pressure of 0.4─0.8 MPa. The elemental sulfur in its turn also oxidizes the mercaptans to disulfides. Emulsion formation accelerates mercaptans and hydrogen sulfide oxidation. Due to a small quantity of the alkaline solution, mixed with the oil, the emulsion with heavy oils is not hazardous for oil transportation, storage and processing. The reaction then proceeds in a pipe and in sales oil tank Т-1. The major portion of the alkaline solution settles in tanks and is re-used for the catalyst complex preparation in tank T-2. The CC from Т-2 is continuously supplied with dosing pump P-1 to mixer М-1. A small portion of the alkali remains in the oil and acts as a corrosion inhibitor in a pipeline and equipment of the refinery.

H2S + 2NaOH → Na2S + 2H2O

RSH + NaOH → RSNa+ H2O

3Na2S + 4O2 + H2O → Na2S2O3 + Na2SO4 + 2NaOH

2RSNa + 0.5O2 + H2O → RSSR + 2NaOH

The DMC-1М process was tested on oil fields of Tateх JS for heavy oil demercaptanization and for demercaptanization of Tengiz oil and revealed a possibility of deep treating the oils for low molecular weight С1 ─ С2 mercaptans and hydrogen sulfide at minimal consumption of the alkali and catalyst.

The DMC-1M process flow diagram