DMC-1 process

The process is used for treating light oils and gas condensates for hydrogen sulfide (from 50 to 5 ppm) and low molecular weight С1-С2 mercaptans (from 600 tо 20 ppm).

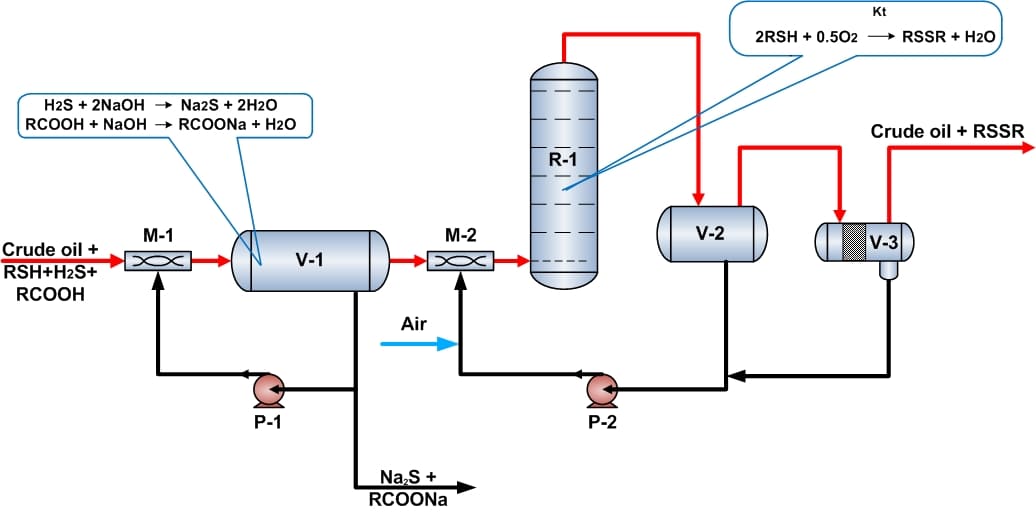

Stabilized oil at 40-60 CC is mixed in mixer M-1 with 0.5-1 % aqueous solution of sodium hydroxide and fed to pre-alkalization device V-1. Selective removal of hydrogen sulfide and naphthenic acids from oil takes place in M-1 and V-1.The oil, treated for hydrogen sulfide and naphthenic acids, enters the bottom of demercaptanization reactor R-1, after having been premixed in mixer M-2 with a catalyst complex (CC) and air, supplied by a compressor. The catalyst complex presents a 10-20 % aqueous solution of sodium hydroxide and IVKAZ catalyst. The mixture of oil, the CC and dissolved air is supplied via distributing collector to reactor R-1, where at a temperature of 50─60 oС and a pressure of 0.6─1.5 МPа oxidation of mercaptans to disulfides takes place following a reaction:

Kt

2RSH + 0.5 O2 → RSSR + H2O

The reactor presents a column with sieve perforated trays. Intensive mixing of the oil and the CC is provided in the inter-tray space of the column due to a high velocity of flow through perforations of the trays. From the top of the column the reaction mixture passes to separator V-2, where the oil is settled from the CC. From the bottom of V-2 the CC is returned to reactor R-1 via mixer M-1. The demercaptanized oil from the top of V-2 flows to separator V-3 to be separated from entrained drops of the CC. From V-3 the oil is loaded to storage tanks.

In 1995 — 1996, two commercial oil demercaptanization plants for 4 MM t/yr capacity were built and put into operation on Tengiz GPZ. The catalyst consumption is 0.05 g/t, alkali consumption is 50 g/t. The process provides removal of methyl- and ethyl mercaptans to residual content below 5 ppm.

In 2006, the DMC-1 plants were modified for DMC-2 technology with capacity increase of each plant to 6 MM t/yr.

DMC-1 process flow diagram