DMC-2 process of oil and gas condensate treatment

DMC-2 process is used for treatment of light oil for hydrogen sulfide and low molecular weight С1–С3 mercaptans without contact of the oil with air. The process consists in extraction of С1–С3 mercaptans and hydrogen sulfide with 10–20 % aqueous solution of sodium hydroxide with its subsequent regeneration by catalytic oxidation of the extraction products with air oxygen.

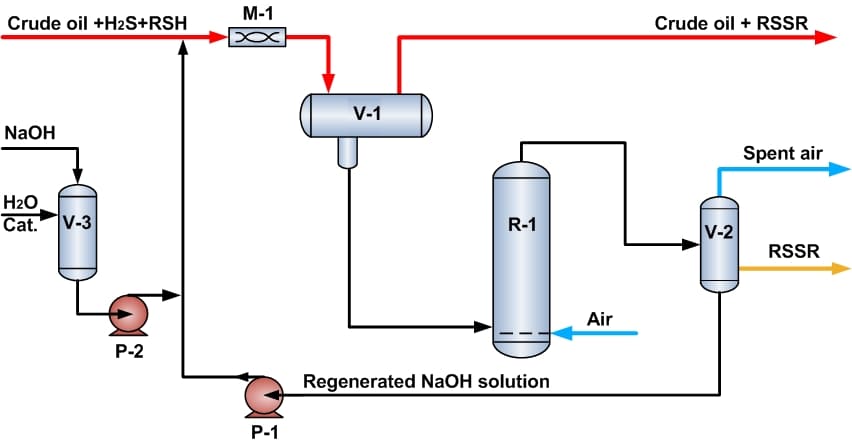

The DMC-2 process flow diagram

The extraction of mercaptans and hydrogen sulfide proceeds in mixer М-1, wherein the stabilized feed and alkaline solution are supplied simultaneously. Then the oil and alkaline solution mixture flows to gravity separator V-1, where the demercaptanized oil is separated from the alkaline solution and sent from the top of V-1 to storage tanks.

The alkaline solution and extraction products – sodium sulfide and mercaptides – flow from the bottom of V-1 to the bottom of regenerator R-1, wherein process air is also supplied from a compressor. The alkaline solution regeneration takes place in the regenerator at a temperature of 50–55о С and a pressure of 0.4–0.5 МPa over IVKAZ catalyst by oxidation of sodium sulfide and mercaptides with air oxygen.

From the top of R-1 the reaction mixture flows to air separator V-2, from the top of which the spent air is sent to incineration and from the bottom of V-2 the regenerated alkaline solution is sent with pump Р-1 to mixer М-1. The disulfides entering М-1 together with the alkaline solution pass into the oil phase. If necessary, the disulfides can be separated from the regenerated alkaline solution.

On the basis of DMC-2 technology two plants of Tengiz oil treatment for 6 MM t/yr capacity have been operating since 2006 on JV “Tengizchevroil” (Republic of Kazakhstan). DMC-2 plants were put into operation by modification of DMС-1 plants.